High Performance Thermoplastic Compounds

We offer a wide variety of products for applications, including automotive, multi-layer film, industrial and packaging.

We offer world-class technology and global availability. Our products can be used with polyolefins and engineering resins.

View our catalog:

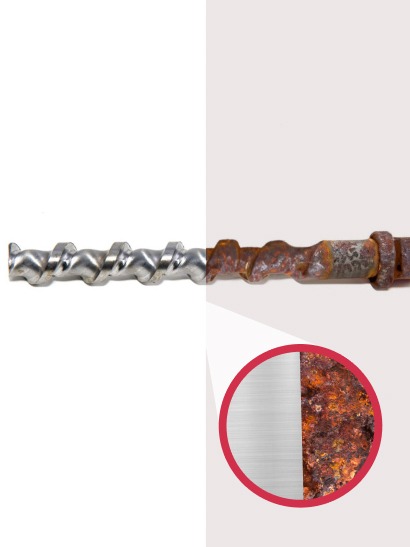

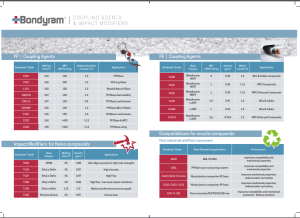

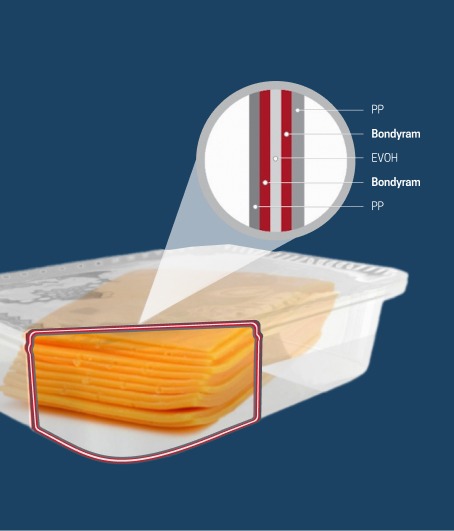

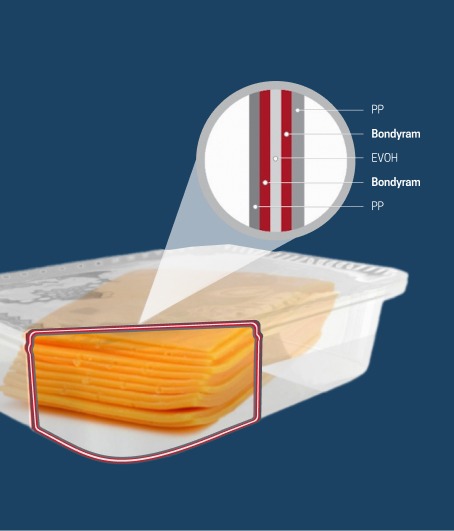

Adhesive resins enable the combination of dissimilar materials in a multilayer structure.

Bondyram® TL is used as a tie layer in coextruded food, cosmetic and pharmaceutical packaging, and also in non-packaging applications such as multilayer pipes and pipe coating, fuel tanks and aluminum composite panels.

Bondyram® TL resins promote bonding between layers in blown and cast films, sheets for thermoforming, blow molded bottles and tubes, coextruded pipe and pipe coating, as well as in extrusion coating processes.

Typical structures in packaging applications are barrier packages with EVOH or polyamide as the barrier material, tied to polyolefin (PE or PP) layers. Bondyram® TL grades also support bonding of a variety of other materials, including PET, PS and aluminum.

View our catalog:

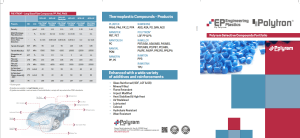

Engineering Plastics Division provides a portfolio of polymer compounds for applications in various industries, modified for special performance:

Increase stiffness, heat resistance, impact modification, flame retardant, UV and weathering, chemical resistance, retention of properties at high temperatures, strength, and dimension stability.

Polyram offers wide range of tailor made E.P compounds suitable for each and every customer’s need!

View our catalog:

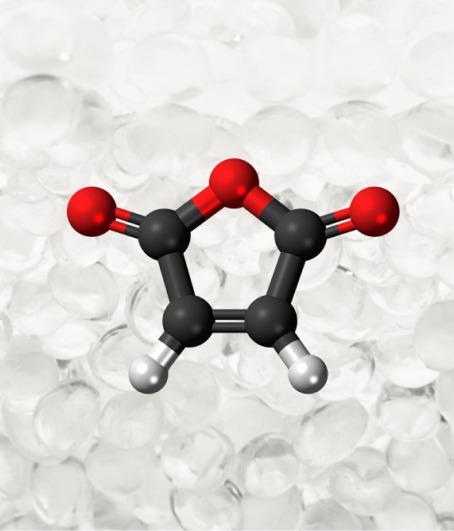

Polytron® is A PP or PA LGF compound , fully impregnated through pulltrusion Process which Offers exceptional Properties for weight and Cost reduction.

With pellet length of 7-25mm and a range of 20%-60% of LGF content ,

Polytron® Products family consist of Tailor made solutions to the Industry’s vast requirements , such as:

- Polytron® LE – Follows OEM’s Strict low emission requirements.

- Polytron® HS – Fulfills highest heat stability requirements.

- Polytron® CR- Offer Climate resistant Properties including UV resistance.

- Polytron® UP- Ultra Performance & safety , with exceptional impact resistance Features, especially at low temperatures.

- Polytron® CE- Cost Effective “One grade fits all Solutions” – offering Materials that are Proofed for all OEMs, in concentrate and full compound options

Increasing the Polytron® Products’ Family through innovation is one of the Key Pillars of moving forward.

Polytron®- Adding value every step of the way. Read our molding guide

5 Top product TDS’s:

Polytron® P60B11-S

Polytron® P20B01

Polytron® P30B01

Polytron® P40B01

Polytron® P50B01

View our catalog: